A key topic for global companies is ESG (environmental, social, and governance). Even in a situation where the importance of the environment and safety is higher than ever, in order to strengthen competitiveness, companies must make quick changes and reflect the trend of the times in their work.

However, there are challenges that must be addressed. There is no way to directly extract reliable data from high-temperature and high-pressure facilities, and most companies around the world maintain facility management methods through direct on-site verification of workers, making it difficult to quantify facility status data to achieve ESG.

There are companies that have come up with a challenge to solve these difficulties in the industrial field.

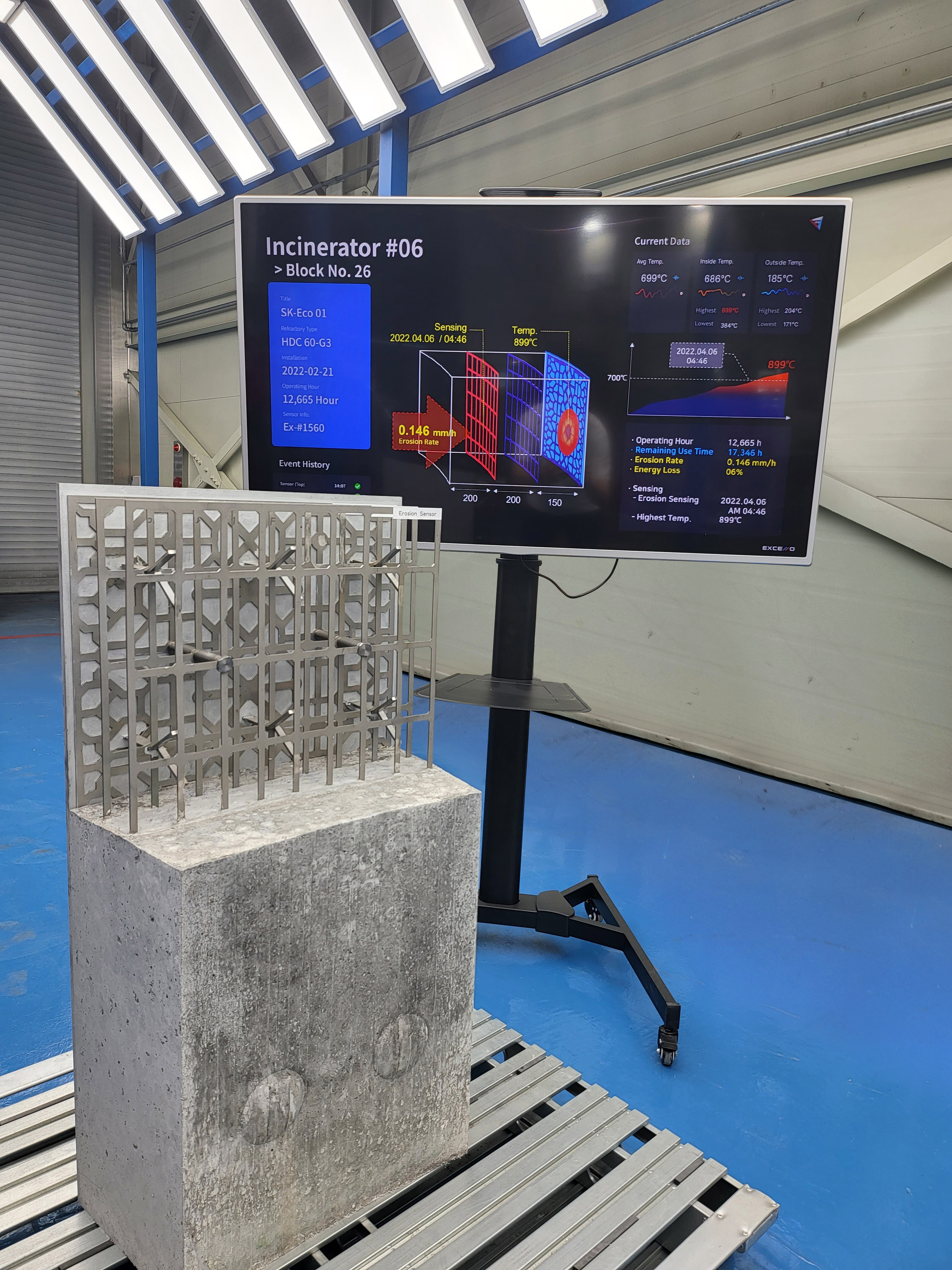

EXCELLO (CEO Park Seong-Jae, www.iEXCELLO.com), a company specializing in DX (Digital Transformation) solutions, is the first in the world to provide a solution that enables the extraction of real-time state data and big data analysis of equipment used in high-temperature and high-pressure environments over 1,600°C. Developed and commercialized successfully.

The EXCELLO IRS (Intelligent Real-time System) solution extracts data through direct measurement inside the high-temperature facility and then provides information necessary for facility maintenance through edge computing in the form of a monthly subscription service. The feature is that the data reliability, which is pointed out as a limitation of the existing external measurement method, has been significantly improved.

First, in the case of an incinerator/cement company, the erosion rate of refractories per hour, the time and rate of loss of energy wasted outside the facility, and the usable time of the refractories until the next repair period can be grasped in real-time through the EXCELLO solution. This information is closely related to the operational efficiency that incinerators/cement companies are facing. This is because sales and operating profit are determined depending on how much the repair period can be minimized and converted into operating hours 365 days a year. With EXCELLO's solution, the incinerator/cement company can not only produce safe continuous production with the same number of facilities and operation methods but also increase sales and improve operating profit.

In the case of steel mills, the performance of refractory materials leads to production efficiency and production cost. In fact, in 2017, Company P attempted to improve the components of the refractory bricks inside the Torpedo Ladle Car (TLC), and there was a case in which the durability of the TLC, that is, the service life, was extended only by improving some components. The EXCELLO solution provides big data-based analysis data such as thickness, thermal conductivity, and energy loss rate that indicate the performance of refractories, so that when a customer replaces refractories when to replace equipment, and how much We present a predictive model that indicates whether fossil fuels should be used. Through this, in the case of steel makers, it is possible to efficiently use the energy costs of hundreds of billions of dollars invested to increase the temperature of the molten metal.

It was not an easy task to apply big data and artificial intelligence (AI) technologies, which were only considered exclusive to high-tech companies, to the traditional manufacturing sector in extreme environments. EXCELLO has invested in intensive technology development over the past five years, and as a result, it has been able to provide high-temperature and high-pressure facility monitoring solution services to global steelmakers. Currently, EXCELLO Solutions is making a name for itself as a company that is good both inside and outside the industrial field. One is to improve production efficiency by minimizing energy loss, and the other is to achieve ESG that helps reduce carbon emissions. So-called, it is the most realistic alternative to catching two rabbits, and it is growing presence as a customized solution for severe disasters.

CEO Park Seong-Jae of EXCELLO said, “Through the EXCELLO solution, workers do not have to go to the site directly through reliable data extraction, analysis, and utilization, and accurate condition monitoring of equipment, such as how much energy loss occurs in which equipment, is Because it is possible, it can dramatically improve worker safety, company cost reduction and production efficiency.”

EXCELLO Co., Ltd. is the company that won the Industry 4.0 category in the incubating challenge program of Europe's Paul Wurth, the world's No. 1 design engineering company, in 2016. Exclusive supply with SAB, a global blower pipe (hot air pipe) supplier In addition to contracts, it provides application and data services to global steel companies P and H companies' blast furnaces, large tangents (the way molten iron flows), blower pipes, and ladles (facilities that move molten iron).

On the other hand, EXCELLO is taking off as a global DX solution specialist by applying solutions and reviewing contracts with overseas global companies based on active service references in various industries such as domestic steel/steel manufacturing, incinerators, cement, and carbon black.

Source : 엑셀로, ESG 탄소배출∙중대재해법 Game Changer | 중앙일보 (joongang.co.kr)

Excello implements real-time tuyere stock monitoring system in a steel mill

The demonstration of real-time surface temperature monitoring system for Tuyere Stock developed by Excello, a South Korean Heat DX company. /EXCELLO Excello, a South Korean Heat DX company, has recently announced the successful implementation of a real-time surface temperature monitoring system for Tuyere Stock at an integrated steel mill in Korea. Excello owns more than 20 S. Korean and internati...

Excello prevents steel industry accidents using cutting-edge technology

If asked when you think of Korea, what companies come to mind, many foreigners would likely answer Samsung or Hyundai. It is irrefutable that these companies have played a remarkable role, representing Korea on the global stage but there are many other Korean companies with unique technology and competitiveness being ready for the global stage. A Closer Look to S. Korea’s Companies series in...

The IRS solution has been selected as a key case of POSCO's BS (Benefit Sharing)project

The IRS solution has been introduced as a major case of the Benefit Sharing project in below. <23. Supplier Information Exchange Meeting Materials for the Second Half of the Year> (Facility BS - Safety Improvement) 1. A device that introduces high-temperature airflow into the furnace at 1,400℃. 1) The operator approaches the blowpipe and measures the outer shell temperature. 2) High risk of explosi...

Park Sung-jae, CEO of Excello, attends the Startup Korea Strategy Meeting

(President Yoon Suk Yeol speaking during Startup Korea Strategy Meeting) (Park Sung-jae, CEO of Excello, attended the Startup Korea Strategy Meeting) (Yonhap News) President Yoon " Startups should be determined to take over the global market'... will do the best" President Yoon Suk Yeol said "the need to boldly change the "startup ecosystem" from one that is government-led to one that is led b...

"DX solution prevents safety accidents in high-temperature operation facilities"

<Sebatian Park, CEO of EXCELLO> <Surface Temperature Sensor> <고온 면 센서> Excello (CEO Park Sung-jae, www.iexcello.com ), a company specializing in Heat DX, recently announced that it has created a successful case of enabling safe operation at the operations site where its solution is applied. "The temperature data monitoring system, which is the most important factor in the steel industry, will...

EXCELLO Co., Ltd has been Certified as Family-Friendly Company

< Certification signboard > < Head Office of EXCELLO > Family Friendly Company Certification by Ministry of Gender Equality and Family High Satisfaction level of Employee Welfare ProgramsA Wide Range of Welfare and Benefit Programs are under Consideration Excello Co., Ltd. (CEO Park Seong-Jae, www.iexcello.com), a company specializing in extreme environment digital transformation (DX) solutions, o...

EXCELLO Co., Ltd Donates to “Youngwoon” Orphanage

< Head Office of EXCELLO > < Youngwoon orphanage in Gwangyang-si > Donations Raised as Part of ESG Management Meaningful Donation to Care Vulnerable Children Continuous Donation as the Social Contribution Activity EXCELLO Co., Ltd (CEO Park, Seong-Jae, www.iexcello.com) donated the amount raised as part of ESG management to caring children in the region on 28th December 2022. < Youngwoon orphanage...

< Military Manpower Administration > < Head Office of EXCELLO > Recognition of Military Service by working at R&D InstitutionRecruitment will start from year 2023 Management System and Preparation has been completed EXCELLO Co., Ltd(CEO Park, Seong-Jae, iexcello.com), specialized company in DX(Digital Transformation) Solution, remarked that the company was selected as a research institute for ...

EXCELLO Co., Ltd is selected as a Excellent Workplace in Jeollanam-Do

< Poto by Seong-Jae park with governor of Jeollanam-do> Selected as the Excellent Workplace in 2022Future Growth Engines with Average Age 37.5 and ration of 52% of Young employees High Satisfaction level of Employee Welfare Programs EXCELLO Co., Ltd(CEO Park, Seong-Jae, iexcello.com), specialized company in DX(Digital Transformation) Solution, remarked that the company was selected as an Excellent...

<Concept Diagram of EXCELLO 'Smart Blocking'> After the Kakao Pangyo Data Center conflagration, securing the safety of facilities that use large amounts of electricity, such as energy storage systems (ESS), is emerging as a national concern. This accident revealed that these facilities have no choice but to shut down the entire power supply once a fire starts and the damage is severe. In p...

"Real-time monitoring of refractories... Targeting the 40 trillion won global market."

<Test blast furnace with IRS refractory from Excello. IRS can grasp the temperature, state, and energy loss rate of refractory materials in real time.> Refractory material may be unfamiliar to the general public. However, it is a huge market worth KRW 1 trillion in Korea and KRW 40 trillion in the global market. We target all industries with facilities that withstand incredibly high temperatures a...

'Blast furnace temperature measurement solution development' Park Seong-Jae Interview with Excello CEO Systematically identify the degree of wear Reduced inspection period and increased operating hours The only company that commercialized the system Acquired 30 patents in Korea and the US "If the temperature drops by about 1 degree from the proper temperature in the steel mill furnace, an ...

Applicable in high temperature and high-pressure environments over 1,600 degrees... Real-time big data analysis of steelmaking and steelmaking Production efficiency ↑ - cost ↓... 'DX' of traditional manufacturing EXCELLO (CEO Park Seong-Jae), a company specializing in DX (Digital Transformation) solutions in the industry, succeeded in developing and commercializing the world'...

[Korea JoongAng Daily] EXCELLO, ESG Carbon Emissions/Serious Accidents Punishment Act Game Changer

A key topic for global companies is ESG (environmental, social, and governance). Even in a situation where the importance of the environment and safety is higher than ever, in order to strengthen competitiveness, companies must make quick changes and reflect the trend of the times in their work. However, there are challenges that must be addressed. There is no way to directly extract reliable data...

<Strategic Alliance Agreement Signing Ceremony, Seung Jae Park, the CEO of the EXCELLO (4th from the left), standing beside Daisuke Ohashi, the President of the Sumitomo Corporation Korea (4th from the right)> <Demonstration of SaaS Data processing system operating through IRS Solution> - Targeting $100 billion global market of steel manufacturing/steel mill, petrochemical, green environment infra...

EXCELLO received ISO 9001:2015 certification

On 21st January 2022, EXCELLO received ISO 9001:2015 certification EXCELLO (CEO Sebastian Park) acquired ISO 9001:2015 certification, a quality management system on Jan. 21st. The application scope of ISO 9001:2015 certification for EXCELLO is all processes affecting the quality of development and manufacturing of refractory erosion and temperature measuring sensors produced by EXCELLO. Through th...

EXCELLO was selected for the 2021 ASEIC Online Incubation Program

On 30th August 2021, EXCELLO was selected for the 2021 ASEIC Online Incubation Program EXCELLO has been selected for the 2021 Luxembourg V-SGBC online incubation program hosted/supervised by the Ministry of SMEs and Startups, ASEIC, Luxembourg Trade & Investment Korea, and Luxinnovation. This program is a project that provides information on the market in Europe to selected companies for about...

JETRO decided to support EXCELLO

On 10th August 2021, JETRO decided to support EXCELLO Recently, according to the growth potential of EXCELLO (CEO Sebastian Park), the Japan Trade Promotion Organization (JETRO) decided to support the provision of information services for three years to strengthen the business engine in Japan. With respect to the interest of Japanese companies toward EXCELLO, JETRO plans to encourage EXCELLO&rsquo...

EXCELLO was granted ‘Inno-Biz’ certification

EXCELLO was granted ‘Inno-Biz’ certification on 27th July 2021 EXCELLO (CEO Sebastian Park) acquired “Inno-Biz” certification. ‘Inno-Biz’, a compounded word of ‘innovation’ and ‘business’, is a certification system granted to technologically innovative SMEs that have secured a competitive advantage by strengthening technological different...

EXCELLO was selected as a beneficiary of “Post TIPS”

EXCELLO was selected as a beneficiary of “Post TIPS” On 1st July 2021, EXCELLO was selected for “Post TIPS” start-up company-linked fund program. “TIPS” is a project that aims to increase the success rate of technology start-ups and foster global star ventures through government funding, such as R&D and commercialization. Companies, finishing “TIPS&rdq...