Smart Ladle System

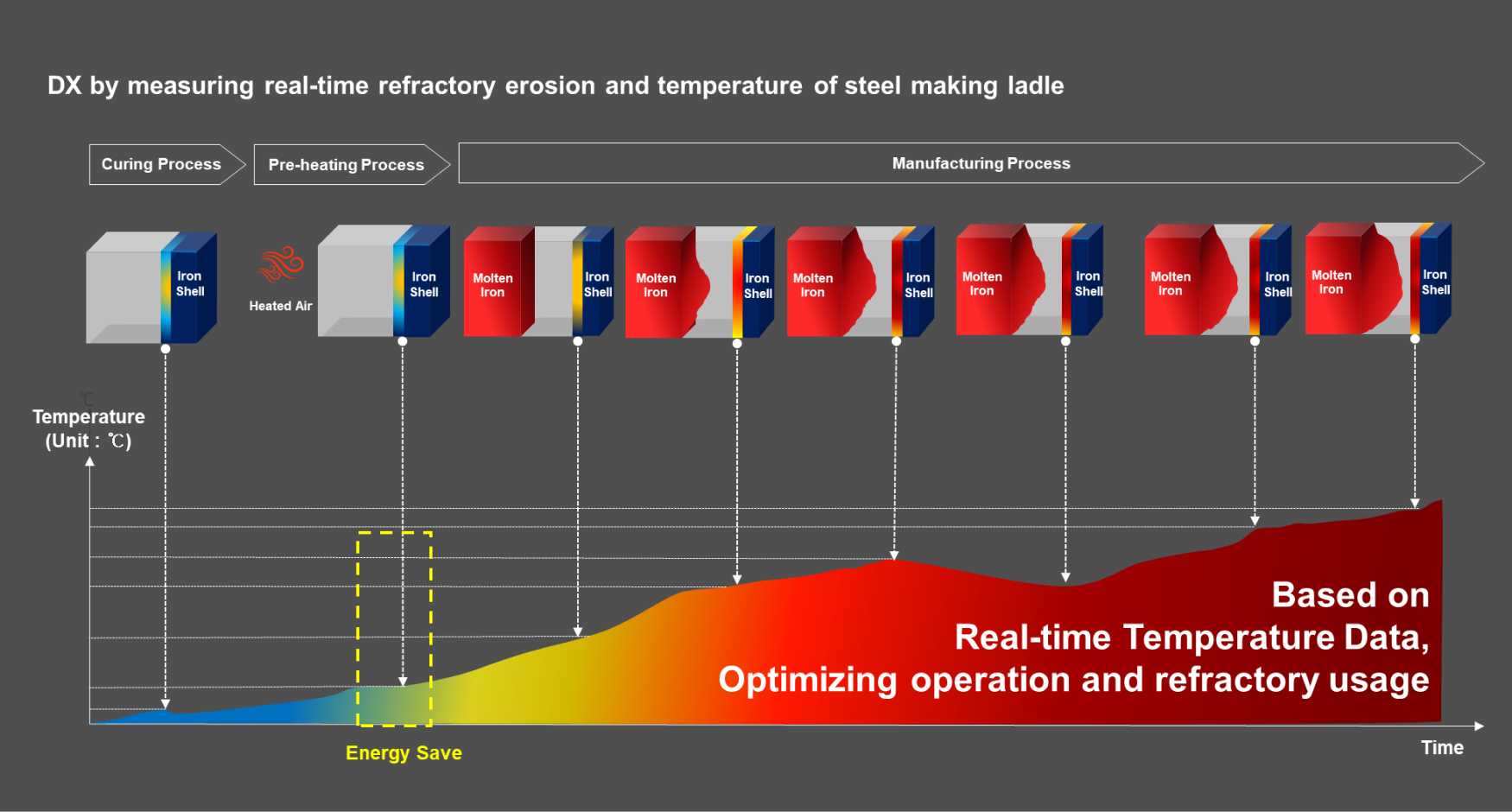

The Smart Ladle System extracts and transmits data in real-time. The traditional ladle system does not generate any data, so in order to monitor the status of the ladle (temperature, location), workers had to physically access it or assess it from the outside. Consequently, the data that could be gathered was very limited, and the reliability of the data (temperature) was very low.

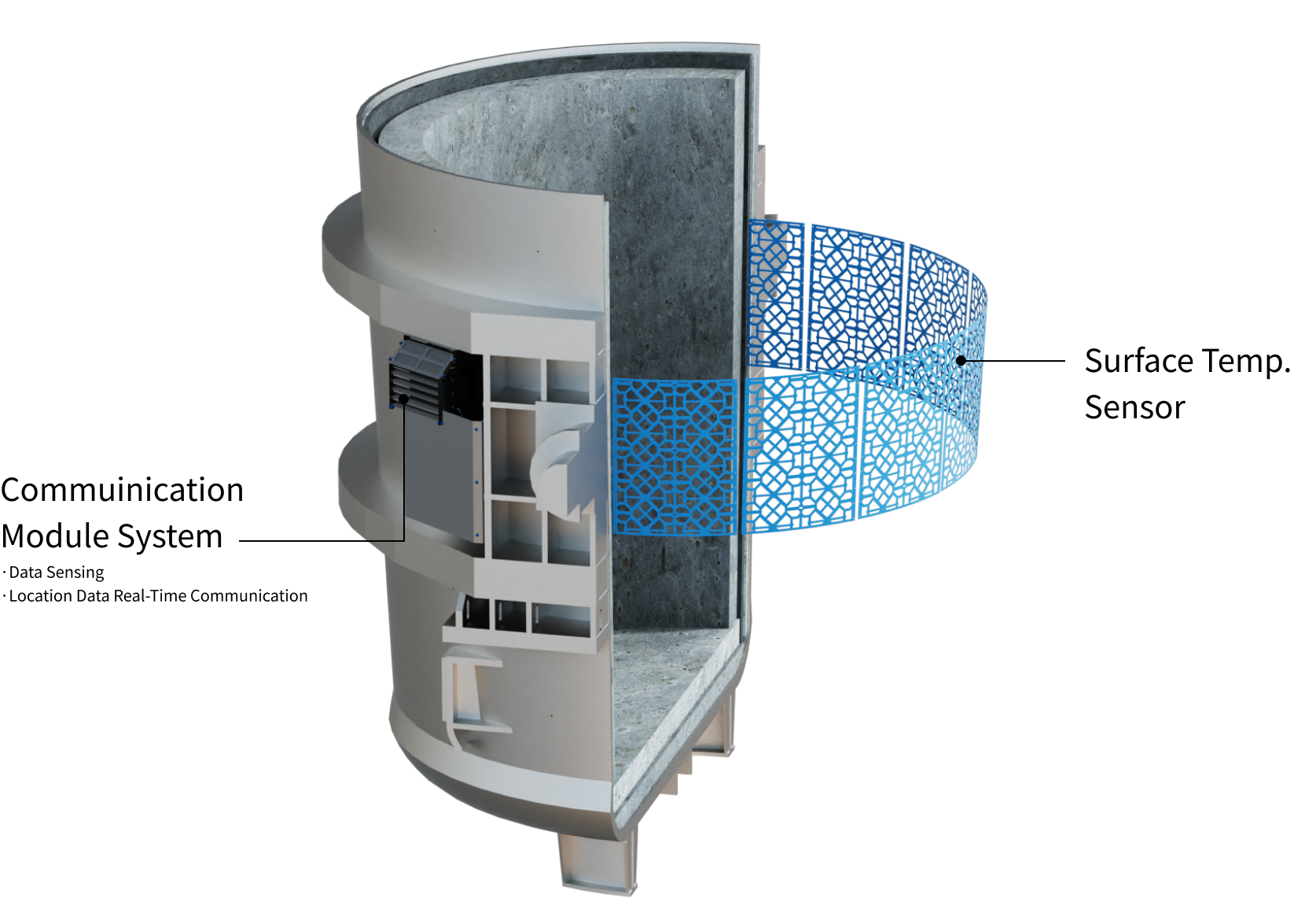

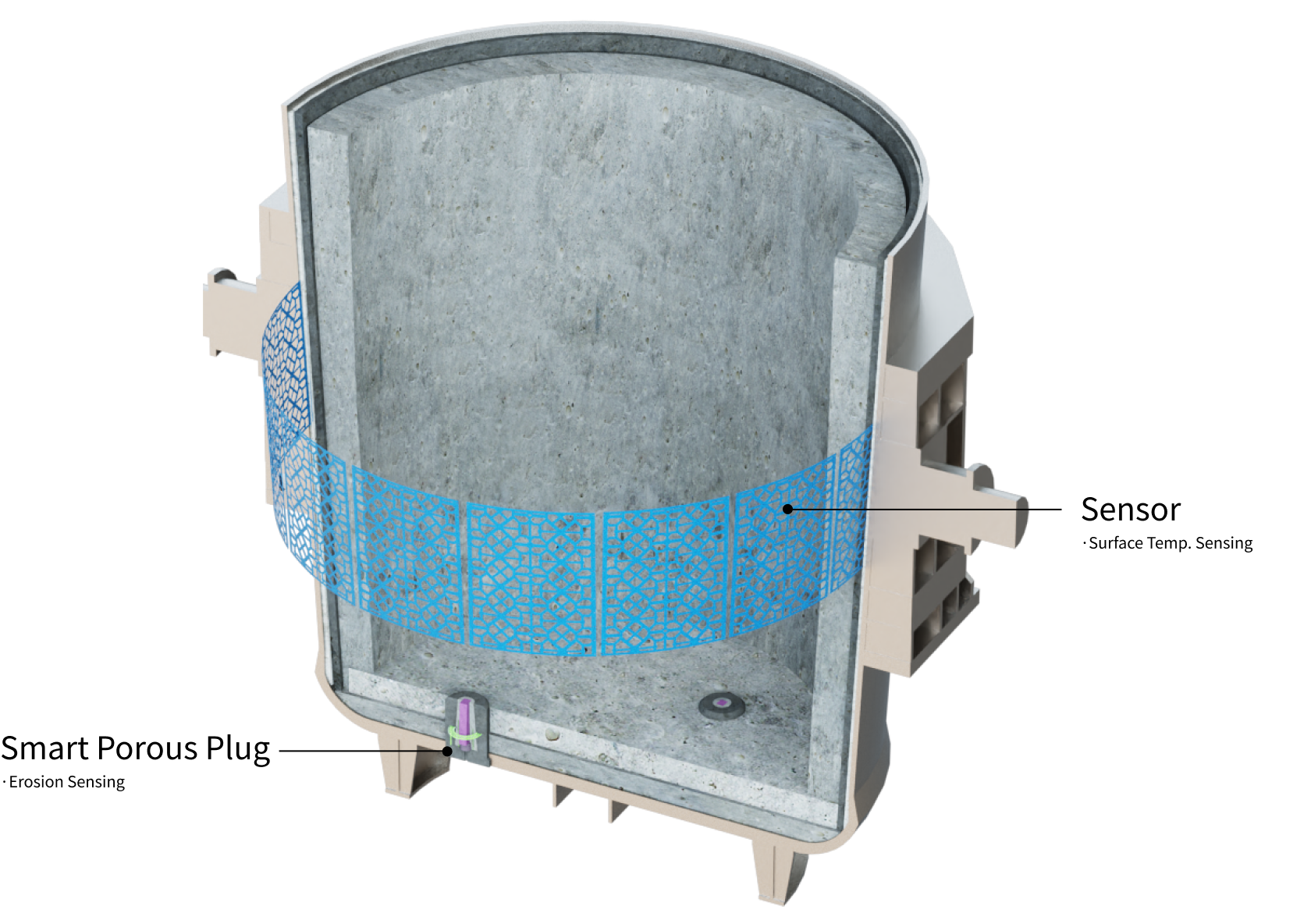

The Smart Ladle System transforms the traditional ladle into smart equipment. It allows for real-time monitoring of the ladle's surface temperature (Surface Temp. Sensor), analyzing data on the wear of the refractory material inside the equipment, data on locations with high heat emission, and the overall energy loss rate of the equipment. Additionally, it enables real-time tracking of the ladle's location.

The Communication Module System collects various sensing data from the ladle and transmits it in real-time. It is specialized for high-temperature mobile heat sources and is a system capable of stable communication in extreme environments.

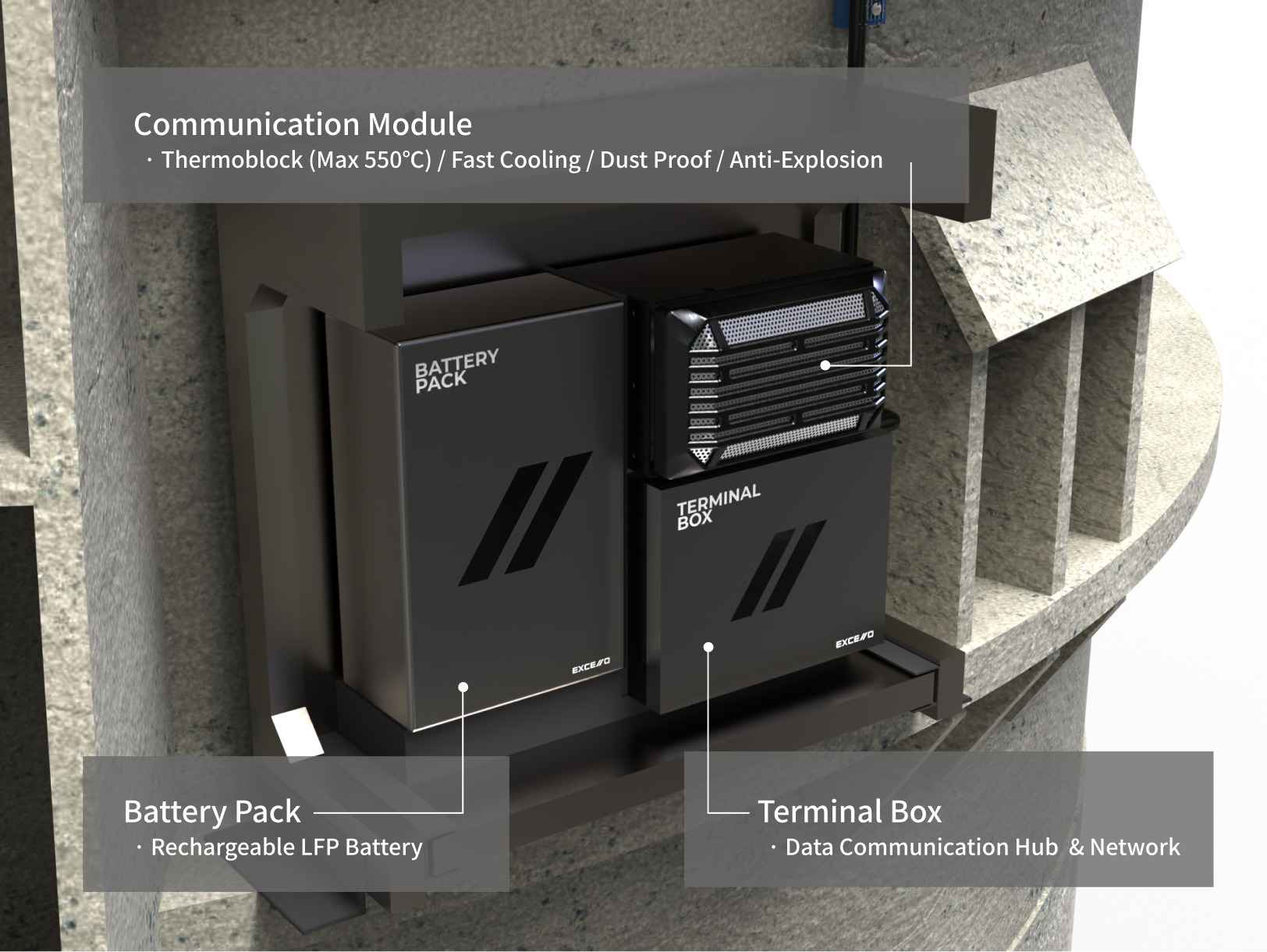

Communication Module

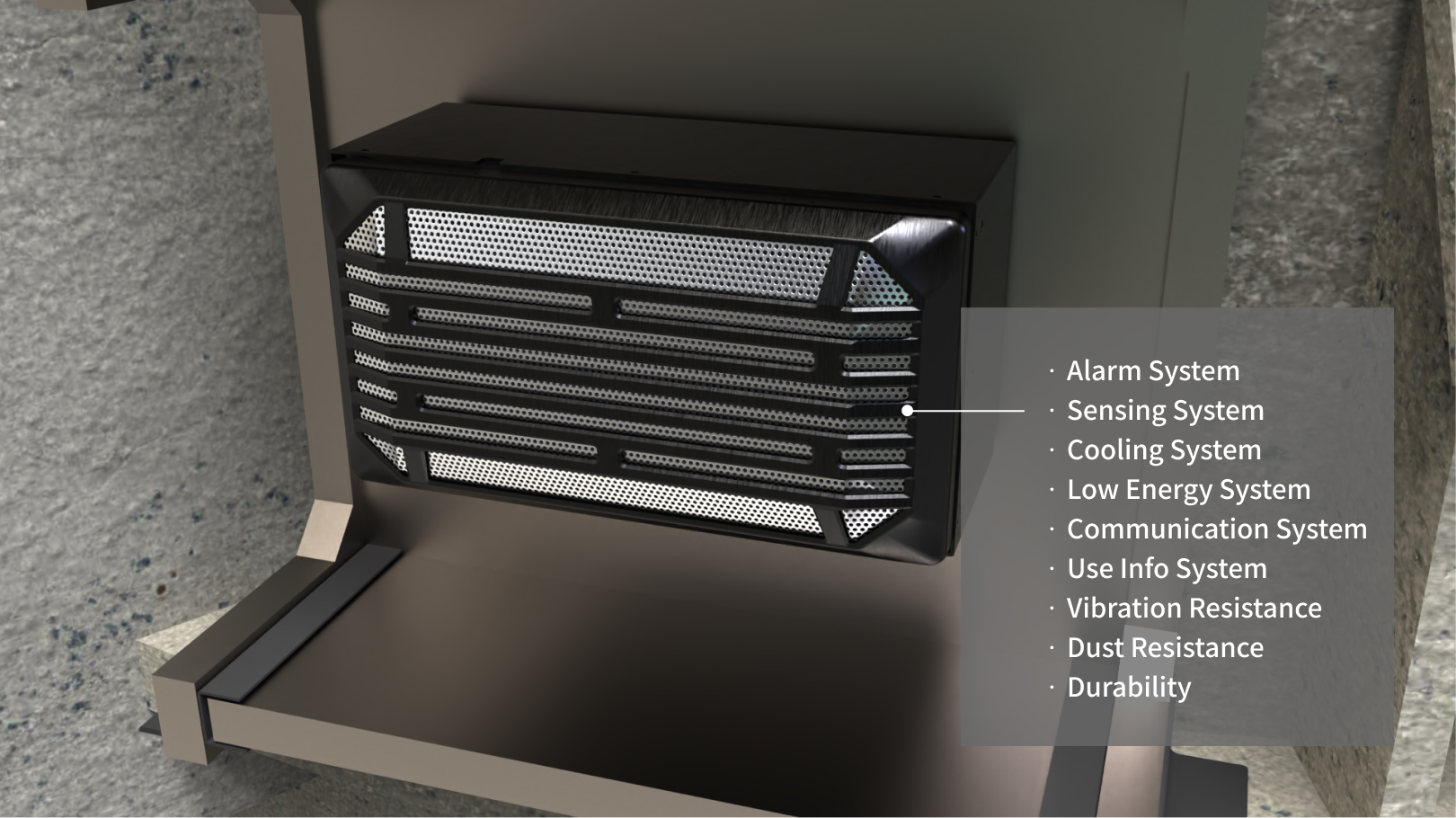

The communication module is capable of stable communication at high temperatures due to its heat shielding and heat dissipation structure. It is equipped with its own cooling system, allowing for stable communication even in high-temperature extreme environments.

| Data | DX |

|---|---|

|

|

The Communication Module System can be applied to all ladles used in various ironmaking/steelmaking processes through standardization (Customization is necessary depending on the installation location and environmental analysis).

Type A

| Applicable Ladle | 80 ton / 150 ton / 300 ton |

| Measurement details | Area temperature sensing or point temperature sensing under 3m2 |

| Composition | Main communication module + Terminal boX + Battery pack |

| Size | 620x 650(Based on External case) |

| Communication | Available for public and private networks (WCDMA, LTE, RoLa, BLE, RF e.t.c.) |

Type B

| Applicable Ladle | 150 ton / 300 ton |

| Measurement details | Area temperature sensing or point temperature sensing under 4m2 |

| Composition | Main communication module + Terminal boX + Battery pack |

| Size | 620x 820(Based on External case) |

| Communication | Available for public and private networks(WCDMA, LTE, RoLa, BLE, RF e.t.c.) |

Battery pack

| Applicable | 150ton / 300ton |

| Material | SUS 304 + Insulation |

| Capacity | Over 315 Ah(1,006 W) |

| Size | 520 x 220 x 130 mm |

| Applicable | 80ton / 150ton |

| Material | SUS 304 + Insulation |

| Capacity | Over 210 Ah(672 W) |

| Size | 320 x 220 x 170 mm |

| Applicable | 80ton / 150ton / 300ton |

| Material | SUS 304 + Insulation |

| Capacity | 105~120 Ah(336~384 W) |

| Size | 320 x 220 x 130 mm |

LFP Battery / Under 400 Wh/L(Energy density) / Rated voltage 3.2V / UN3480, UN3481 Certification / MSDS Provide

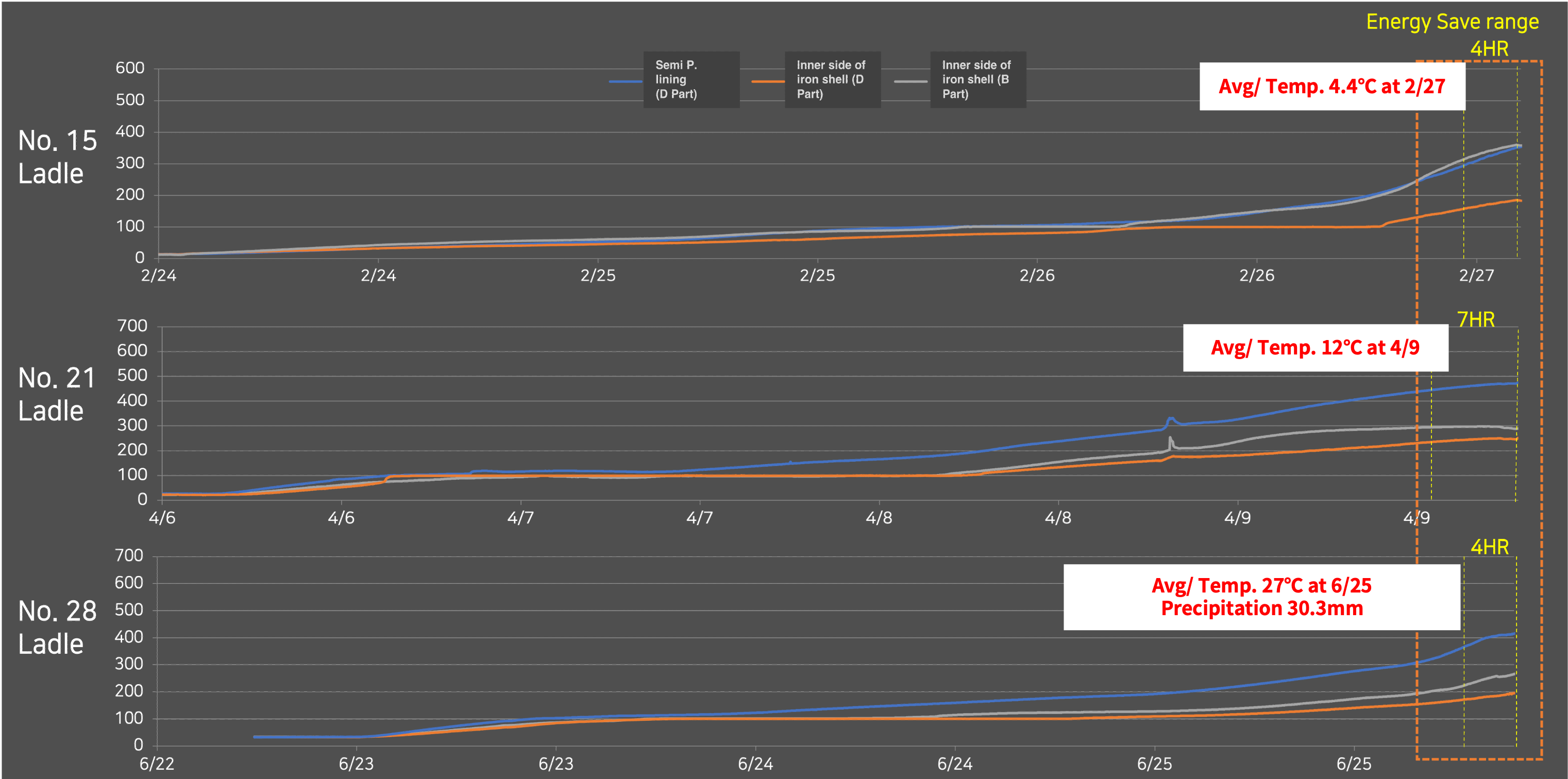

The optimal drying time is analyzed during ladle preheating. By understanding the ladle drying time affected by weather, temperature, and humidity, it is possible to analyze the optimal drying time. By accurately determining the input and termination points to prevent overcooking, it is possible to save ladle energy according to environmental conditions.

| Data | DX |

|---|---|

|

|

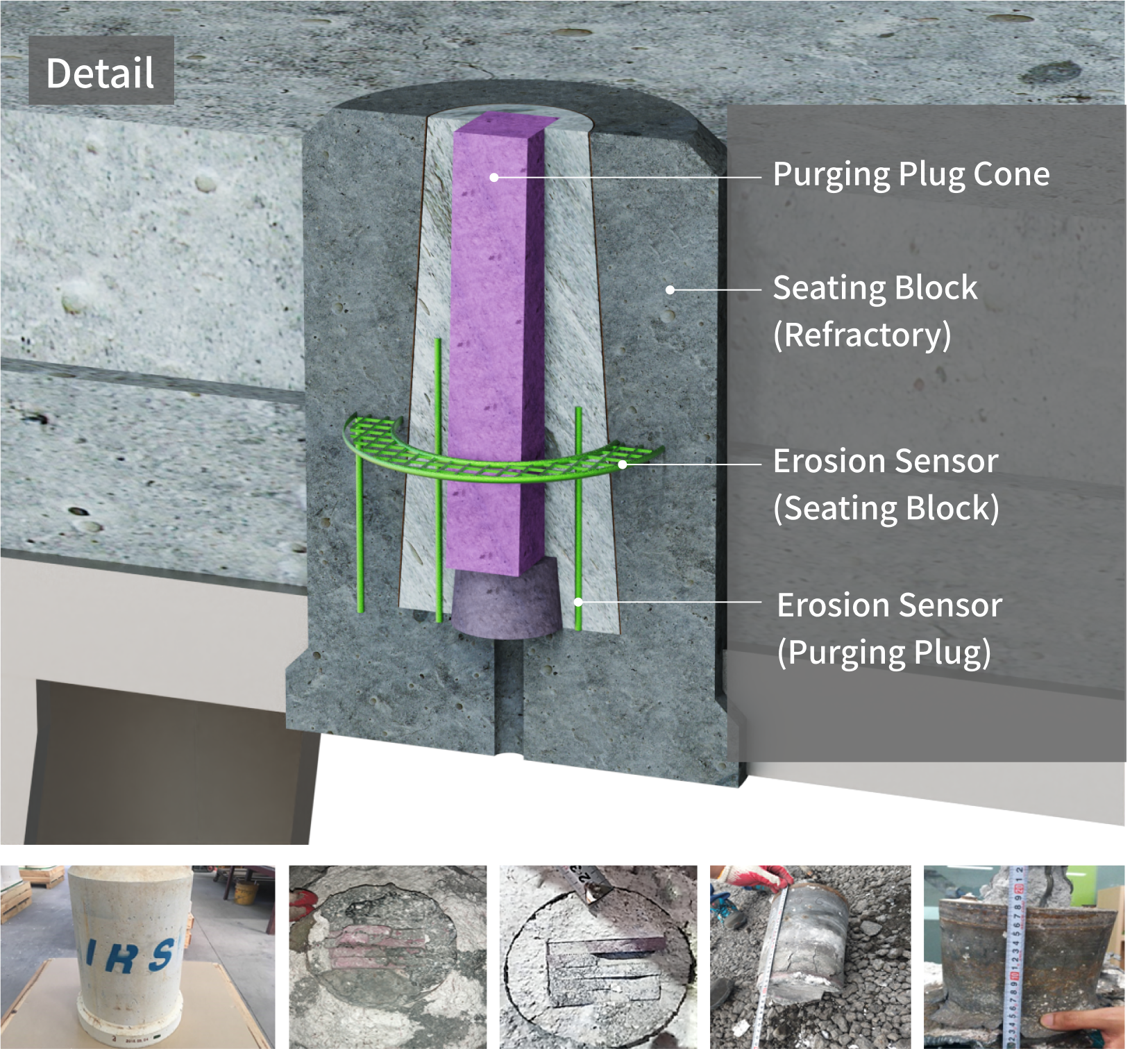

Smart Porous Plug (Erosion Sensor)

The Smart Porous Plug integrates the refractory and erosion sensor into a single unit, allowing for real-time monitoring of refractory erosion data during operation and enabling the prediction of the refractory's future usable life.

| Data | DX |

|---|---|

|

|