IRS

Intelligent Real-Time System

Intelligent Real-time System

| Sensor | Data | DX |

|---|---|---|

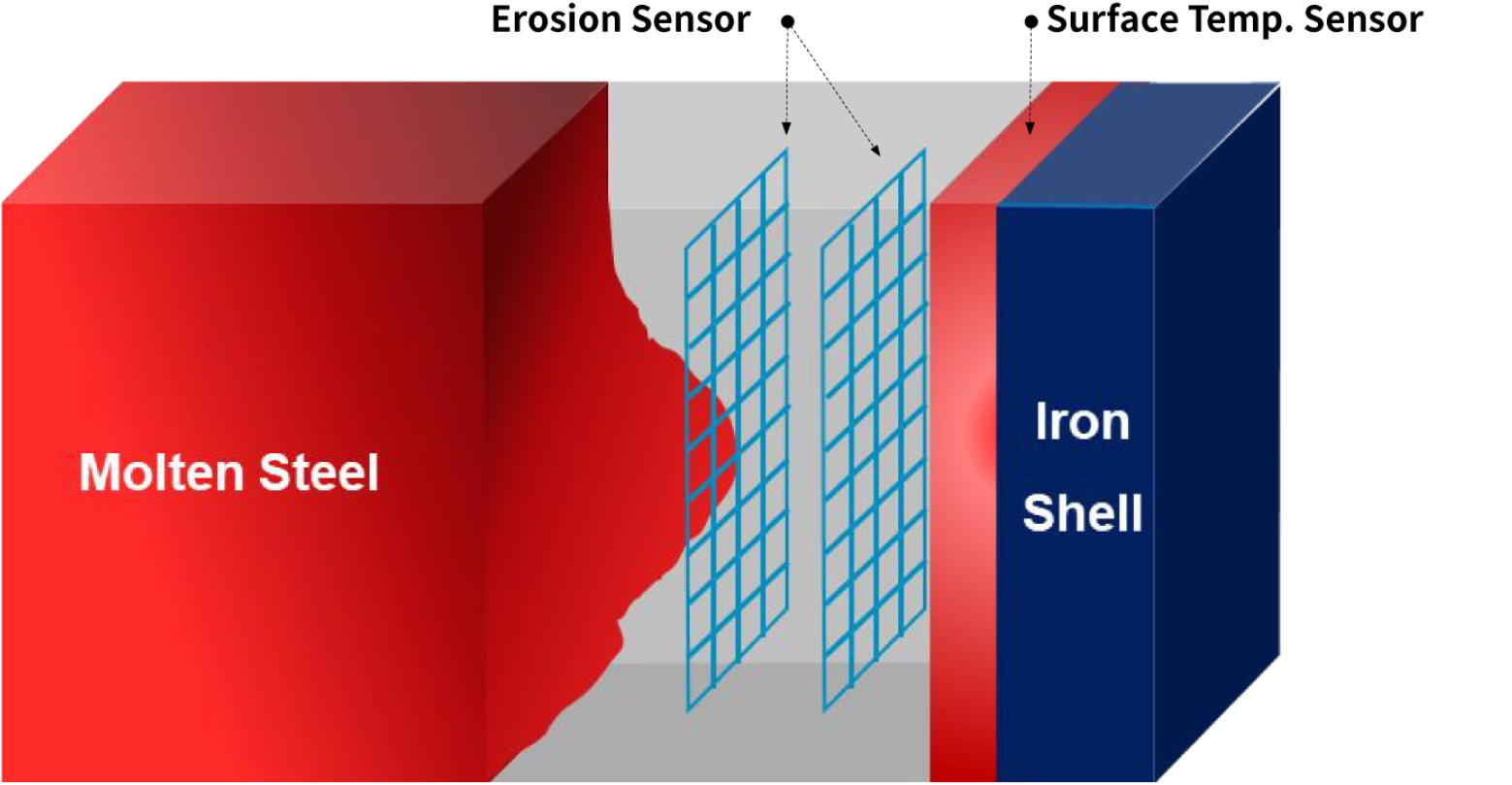

| Erosion Sensor |

|

|

| Surface Temp. Sensor |

|

IRS(Intelligent Real-time System) extracts Data of equipment and refractory under extreme environment.

Erosion Sensor and Surface Temperature Sensor DX solution enables to monitor refractory erosion status (Location and Depth) through Big Data analysis on surface temperature changes due to erosion.

IRS is the most optimized solution for Carbon Neutrality and ESG.

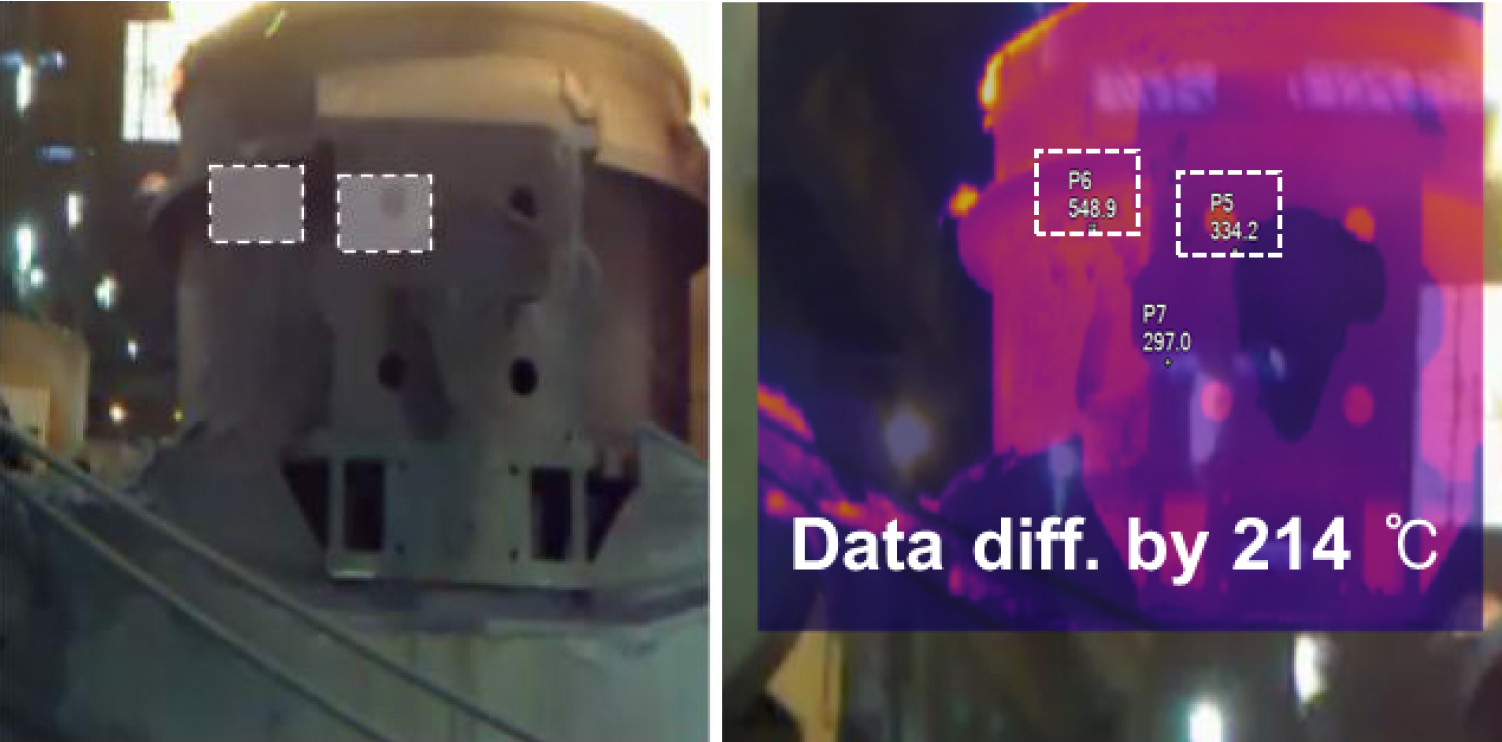

Surface Temp. Sensor

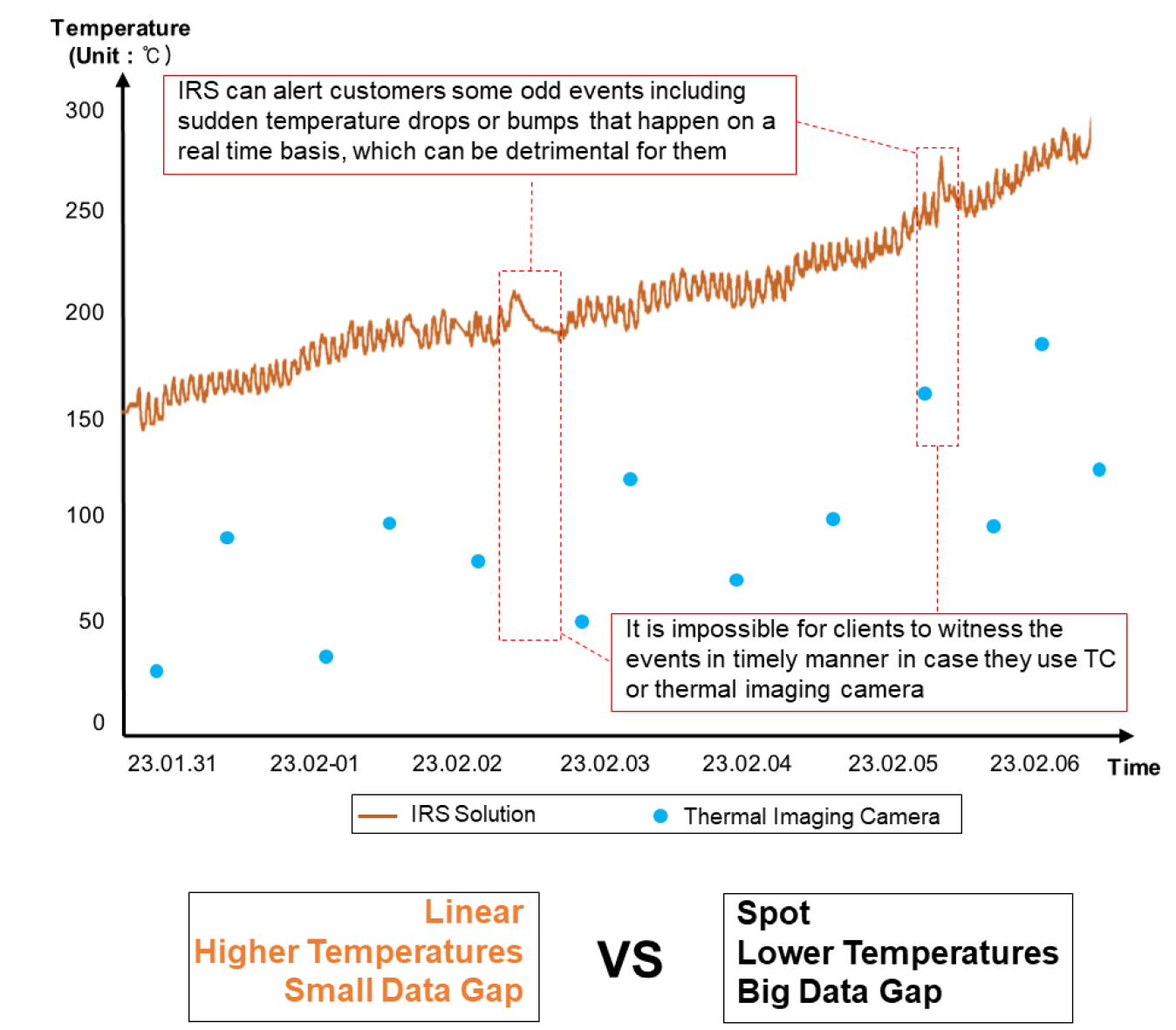

< To-Be Method by IRS Solution >

IRS would show customers a) real-time status of the equipment and b) the trends of temperature data over time for customers’ equipment on a real-time basis, which indicates three crucial points

- Higher range of detectable temperature (up to 1,700℃)

- Lower error rate (0.5% at 1,700℃)

- Data Linearity (detectable during actual operation)

< As-Is Method by Thermal Imaging Camera >

Thermal imaging camera provides less trustworthy data and less operational optionality than IRS.

Surface Temp. Sensor

| IRS Solution | Thermal Imaging Camera | |

|---|---|---|

| Temperature Measurement Range |

Wide Measuring Range (-270℃ to 1,700℃) |

Moderate Measuring Range |

| Sensitivity | Very High | Poor |

| Linearity | Linear | Non-linear |

| Long Term Stability | Stable | Moderate |

| Accordance of data | Very High | Poor |

| Detection Depth | In-depth Detecting Detecting inner condition of equipment |

Limited only outer surface of equipment |

| Curvature to detect | Possible For any kind of curvature equipment |

Not possible Point sensing for only flat area |

| Range of detection | Size of Entire Equipment | Size of Pulse |

| Method of detection | Automatic | Manual by Operator |

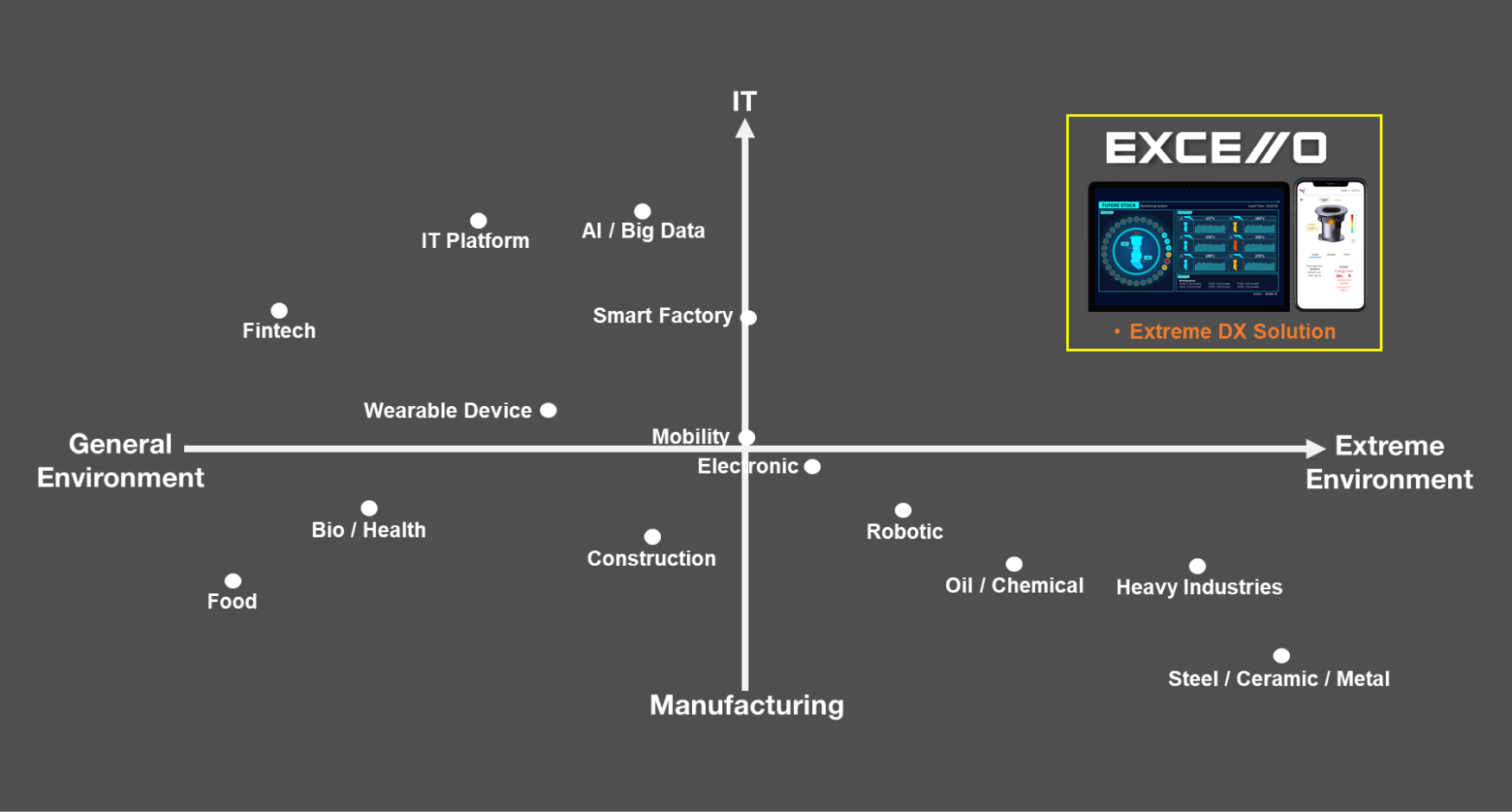

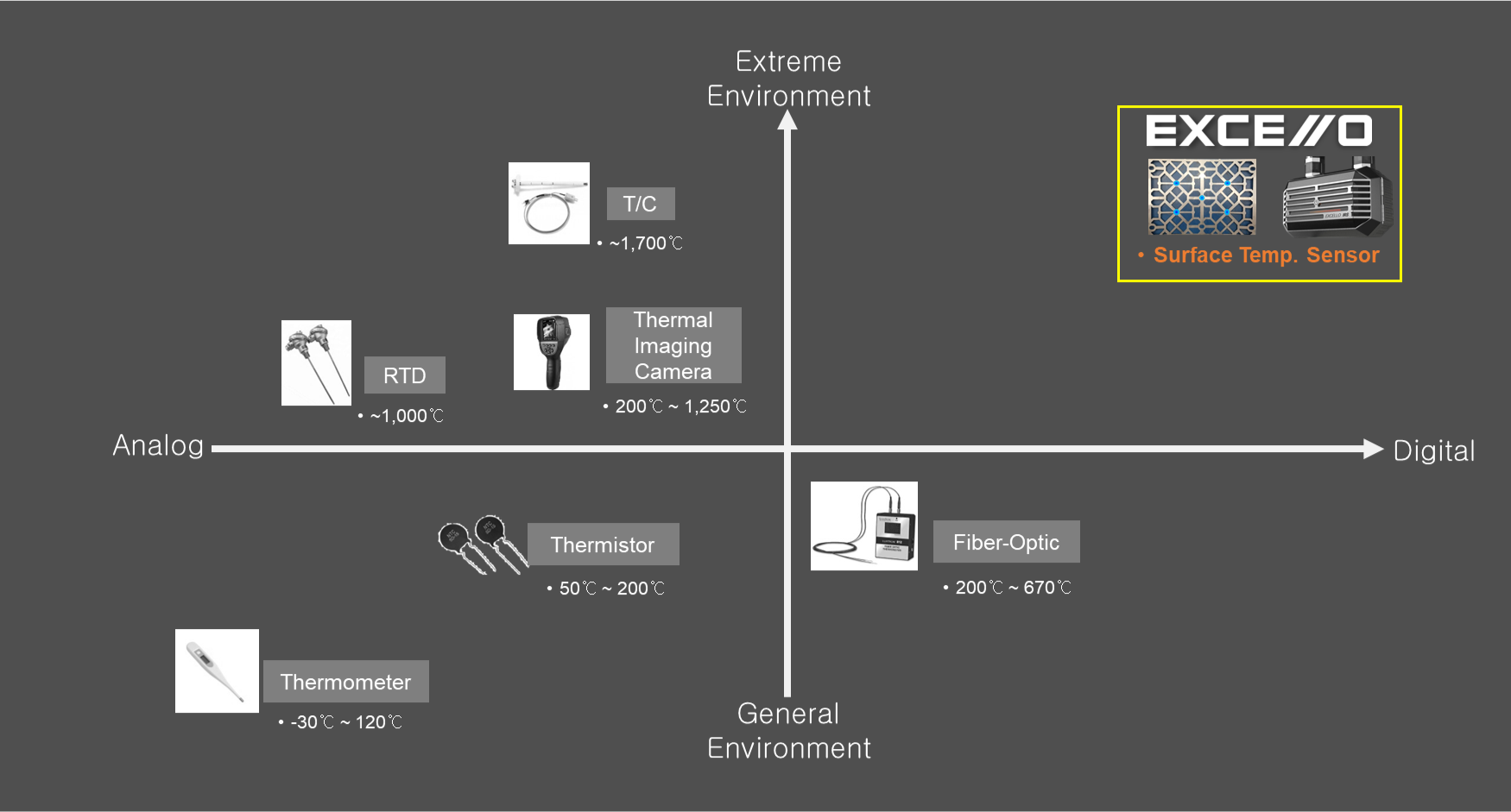

Strategic Positioning

Strategic Positioning